Rubber ball tampo printing machine with oval belt conveyor

Product:ball tampo printing machine

Model:DX-B6C-65

Brand:DSTAR

Printing color:1-6 Color

Printing plate size:150*300mm

Ink cup size:φ130mm

Max printing ball diameter:φ65mm

Printing speed:600 pcs/hr

Rotate:automatic

Feeding and Unloading:Manual

Power:AC220V/3800W

Dimension:L300*W200*H165cm

N.W:1500KGS

- Silicone pad

- Pad printing plate

- Ball fixture

- Printing ink

- Ink cup

In the ever-evolving world of printing technology, the Rubber Ball Tampo Printing Machine stands out as a groundbreaking innovation, designed to meet the diverse and intricate needs of modern printing. Whether for sports equipment, promotional items, or custom toys, this machine offers unparalleled capabilities that set it apart from conventional printing methods. Here’s a closer look at the main features that make this machine a game-changer in the industry.

Multi-Color Tamp Printing

One of the standout features of the Ball Tampo Printing Machine is its ability to perform multi-color tamp printing with exceptional precision and clarity. This machine can print multiple colors in one seamless operation, ensuring vibrant, high-quality images and logos on rubber balls. The multi-color capability significantly reduces production time and costs, while enhancing the visual appeal of the printed products.

Automatic Rotation for Double-Sided Printing

Printing on spherical objects like rubber balls presents unique challenges, especially when it comes to achieving consistent quality on both sides. The Rubber Ball Tampo Printing Machine addresses this with its automatic rotation feature. This innovative mechanism rotates the ball, allowing for precise, double-sided printing without manual intervention. The result is a flawless, uniform print on both sides, increasing efficiency and productivity.

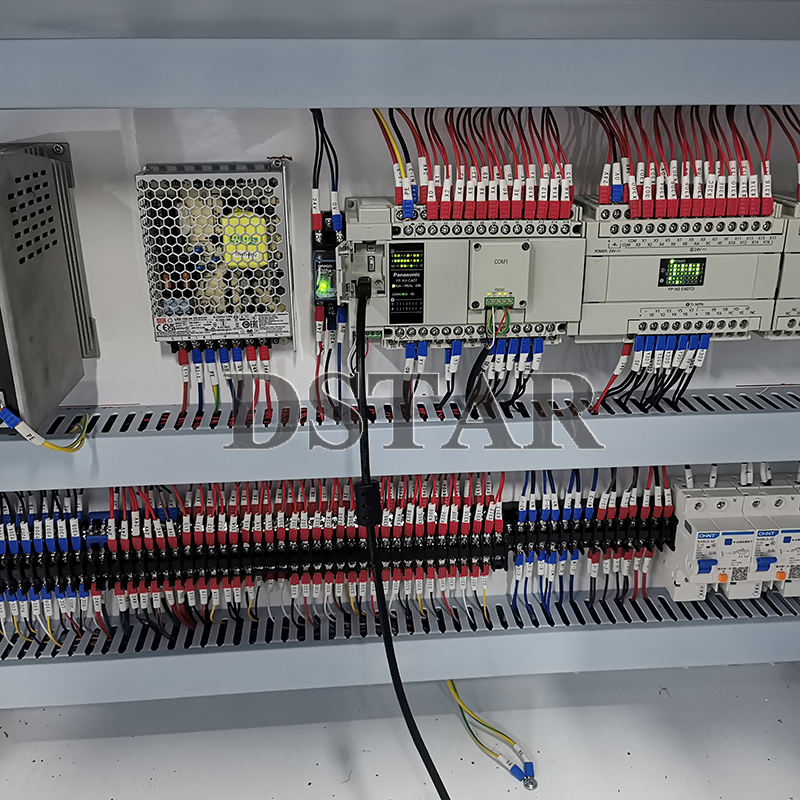

Advanced PLC Control

At the heart of the Ball Pad Printing Machine is its advanced PLC (Programmable Logic Controller) system. This sophisticated control unit ensures the machine operates with maximum efficiency and reliability. The PLC system provides intuitive controls, allowing operators to easily program and manage printing processes, adjust parameters, and monitor performance in real-time. This level of control minimizes errors and optimizes production, making the machine suitable for high-volume manufacturing environments.

Customized Silicone Pads

To achieve the best printing results, the Rubber Ball Tampo Printing Machine uses customized silicone pads tailored to specific printing requirements. These pads are designed to conform perfectly to the contours of rubber balls, ensuring even ink transfer and high-definition prints. The ability to customize silicone pads means that the machine can accommodate a wide range of ball sizes and designs, offering unparalleled versatility and flexibility.

Additional Features and Benefits

- High-Speed Operation: The machine is capable of high-speed printing, significantly reducing production times while maintaining top-notch quality.

- Durable Construction: Built with robust materials, the Rubber Ball Tampo Printing Machine is designed for long-term use, ensuring reliable performance over time.

- Easy Maintenance: The machine’s design simplifies maintenance, with accessible components that allow for quick cleaning and repairs, minimizing downtime.

- User-Friendly Interface: The user interface is designed for ease of use, enabling operators of all skill levels to manage the printing process efficiently.

- Environmentally Friendly: The machine uses eco-friendly inks and materials, supporting sustainable manufacturing practices.

Conclusion

The Rubber Ball Printing Machine is a revolutionary tool that combines advanced technology with practical features to deliver superior printing solutions for rubber balls. Its multi-color printing capability, automatic rotation for double-sided printing, and advanced PLC control make it an indispensable asset for businesses seeking high-quality, efficient, and versatile printing solutions. With the ability to customize silicone pads, this machine caters to diverse printing needs, making it a must-have for manufacturers looking to stay ahead in a competitive market.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat