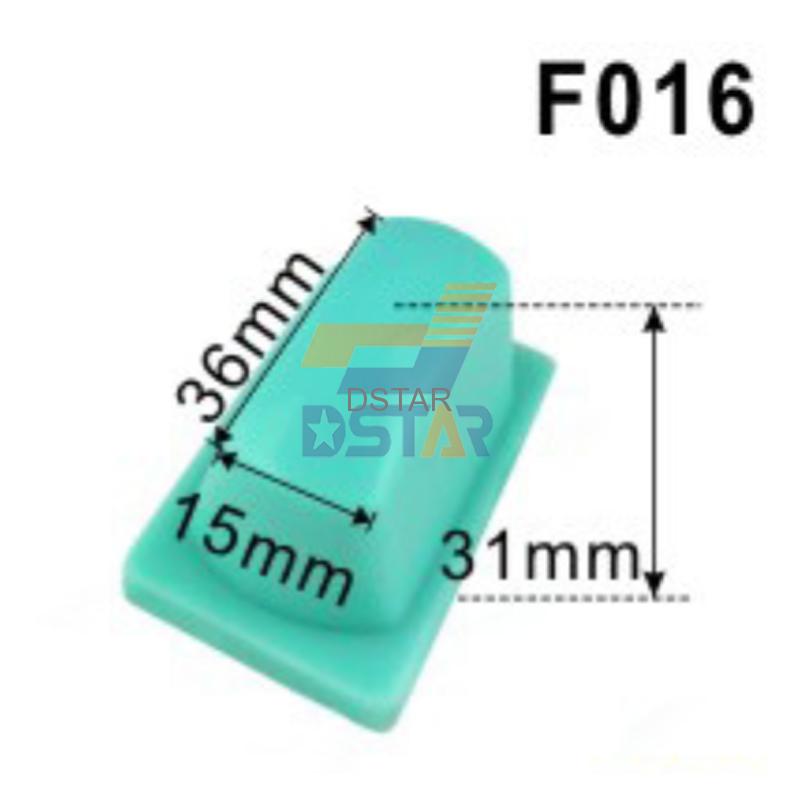

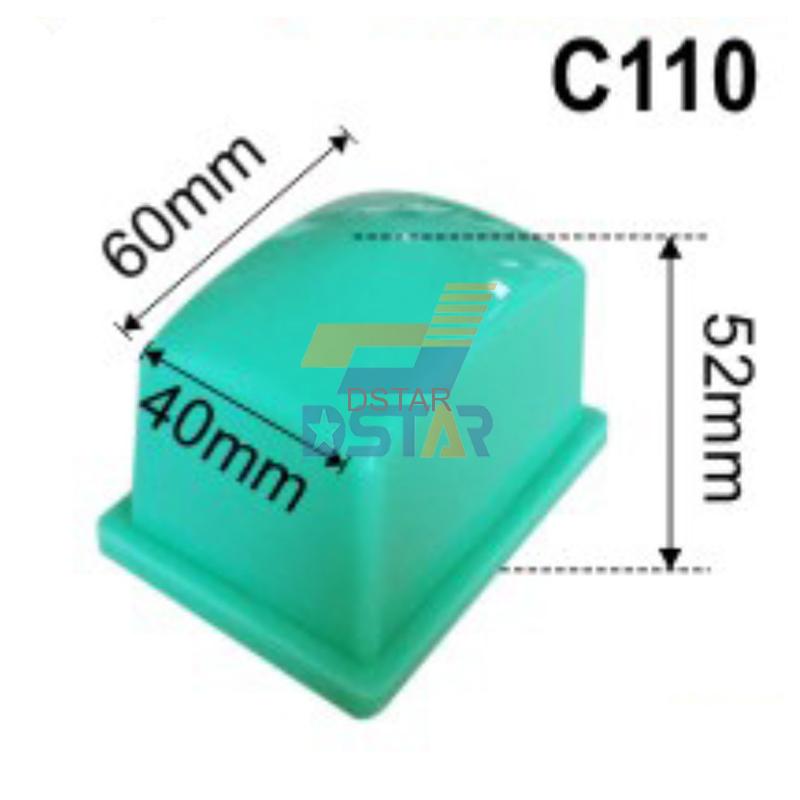

silicone pad for pad printer machine

Material:silicone

Hardness:75-90 shore

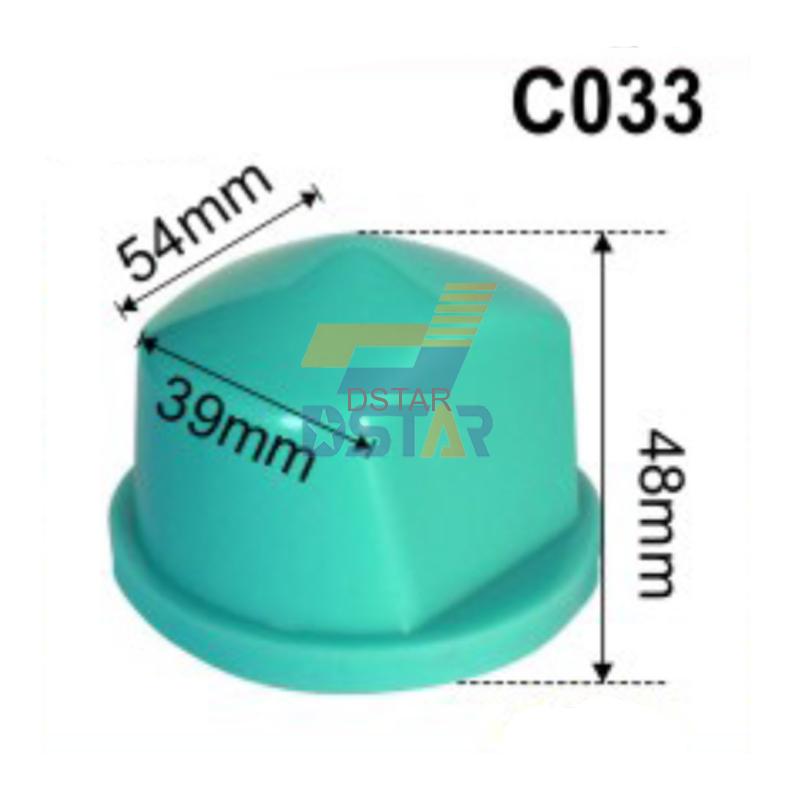

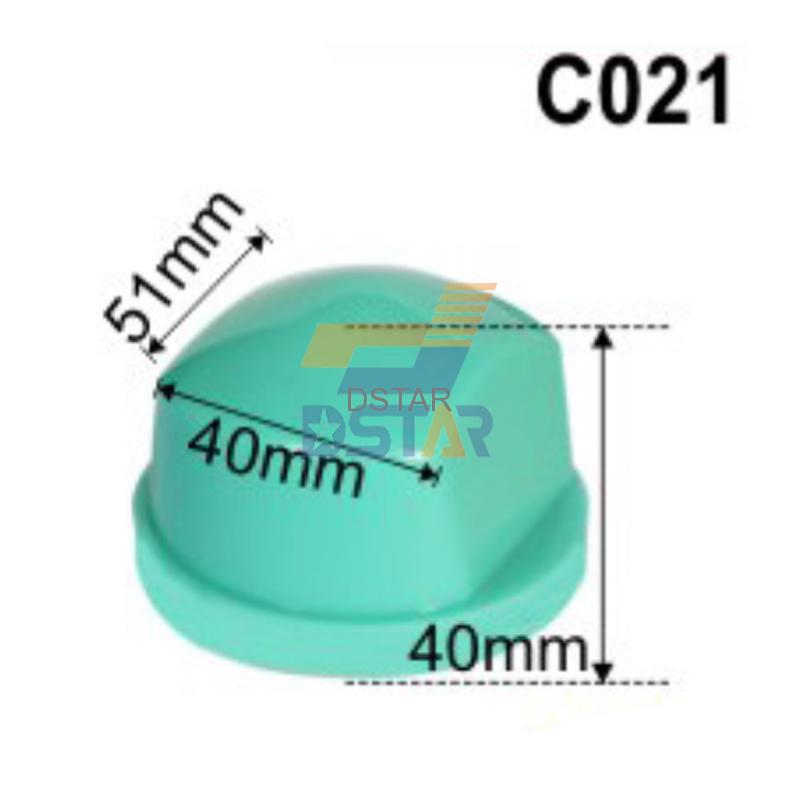

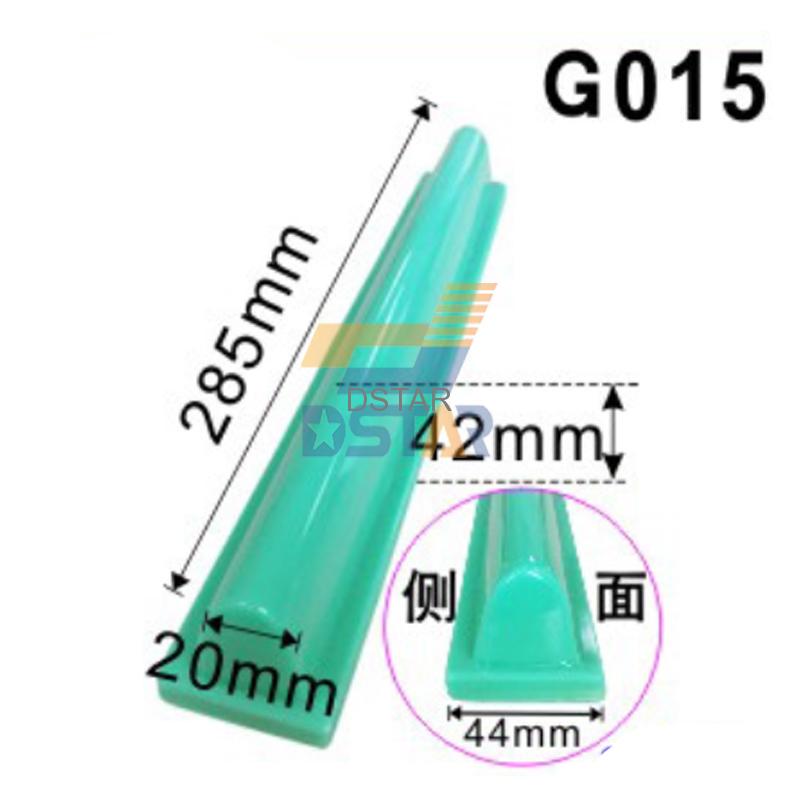

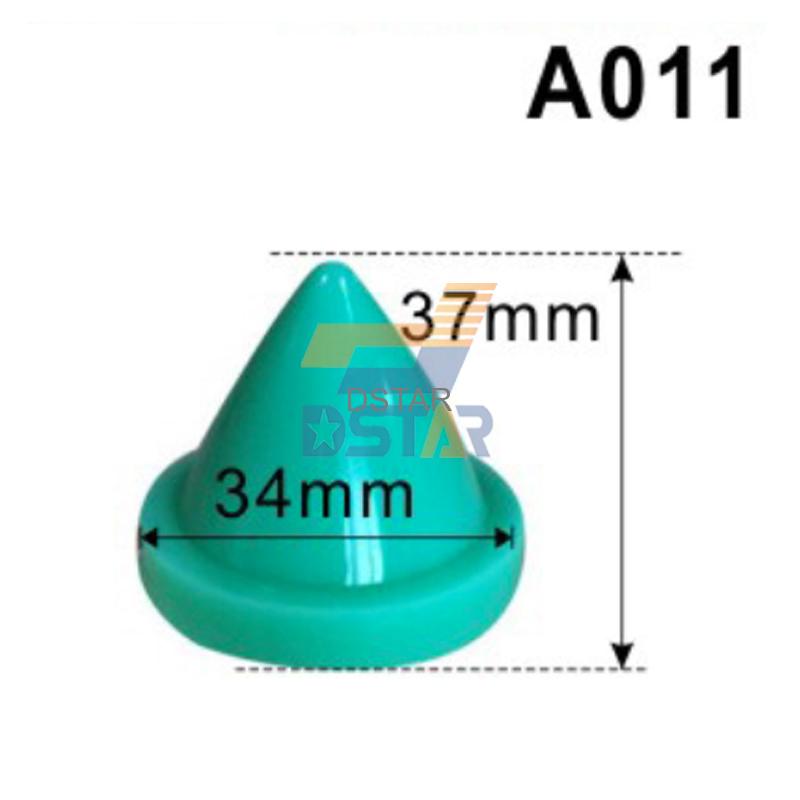

Size:vary sizes

How to select right pad for your pad printer machine?

Size, shape and hardness are the three most important considerations in choosing a pad for a given application.

The size is determined by the size of the image to be printed, and by the size of the machine. Measuring the image diagona,the pad should be 20% larger to prevent image distortion. The machine needs tobe able to compress the pad far enough to pick up and transfer the entire image in an even motion. In addition, the pad must not interfere with the ink cup or other parts, and it must not roll off the edges of the cliché during image pick up.

The shape of the part determines the shape of the pad. There are three basicshapes from which all standard pads are derived (with the exception of rotarypads.) The three basic shapes of conical, rectangular, and roof-shaped areillustrated to the right.There are many variations of each of these three basic shapes. To determiningwhich pad works best for a specific application have your supplier test print yourparts for you.Once you have the correct pad you need to concern yourself with setting theproper compression and correctly locating the pad.Compression should always be set for the minimum amount necessary to pickup and transfer the image. Over compression causes excessive pad wear as wellas poor transfer efficiency.In set-up, the pad should be located so that its point is not in the image areawhen the image is picked up. The point is the first place a zero degree angle willbe created during compression. Having the point in the image can result in a voidin the printed image in that location. It is helpful to keep a record of set-downpoint and machine compression settings if you’re going to run a job frequently,so as to expedite machine set-up.

Hardness is the last of the three main considerations in choosing a pad.Hardness comes into play for three main reasons. First, the same pad of two different hardness requires different amounts of energy to compress the same distance. A given machine may not be able to compress the harder of the two.Second, a hard pad may damage the part you wish to print, thus limiting you to pads of a lower duro meter.Third, textured surfaces are more successfully printed using harder pads.(Some textures are very difficult or impossible to print regardless of what pad you use.)

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat