UV curing machine used as post press equipment after screen printing

Model:UV2-600

Lamp:5.6KW*2 (Fan cooling)

Lamp power adjustment:50%-100%

Belt width:600mm

Belt material:stainless steel

Machine power:12KW/AC380V 50Hz/3 Phase 5 cables

Machine size:L230*W91*H165cm

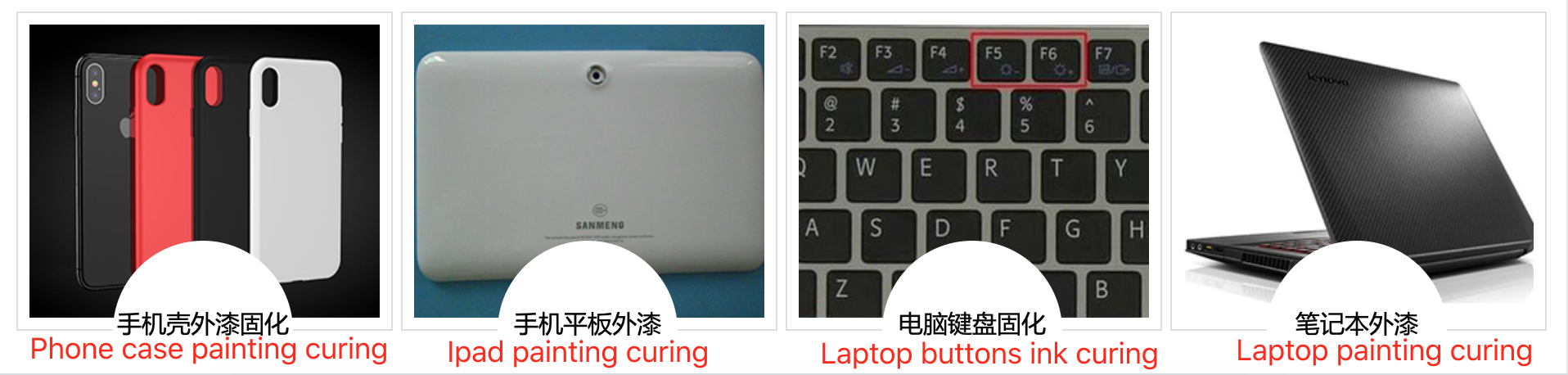

Application of UV curing machine:

flat surface product ink or painting curing

Features:

1. It has beautiful appearance, light volume and space saving.

2. Wide application, reliable quality, safe use and convenient operation

3. Easy to operate, one key switch

4. Fast curing speed, improve production efficiency

5. The advanced heat dissipation system automatically controls the heat dissipation time to ensure that the workpiece is not affected by temperature and prolong the service life of the lamp.

Ultraviolet is the abbreviation of (Ultra-VioletRay). The ultraviolet wavelength used is in the industrial application range of 200nm to 450nm. The manufacturing process that uses ultraviolet rays to use “ultraviolet heatable materials” and heats, and is equipped with “UVCuring” process.

UV curing machine is a kind of mechanical equipment that can emit usable strong ultraviolet rays. It has been widely used in printing, electronics, building materials, machinery and other industries. The types and styles of UV curing machines are different due to the different products they are cured, but their ultimate purpose is the same, which is to cure UV paint or UV ink. The UV curing device is composed of five parts: a light source system, a ventilation system, a control system, a transmission system and a cabinet.

Application of UV curing:

- Offset printing:

The Offset printing has become the mainstream printing process for high-end prints due to its fine craftsmanship and rich colors. It has strict requirements on the expansion and deformation of printed materials and adaptability to high-efficiency and high-speed printing. The UV curing machine supporting offset printing must achieve the light curing of the printed matter. The temperature should not exceed 50°C to prevent the prints from being stretched or deformed. The light-fixing speed must reach 8000 sheets/hour. The intelligent automatic delivery machine can adapt to the automatic high-speed printing requirements of offset printing. The UV lamp used in the conventional UV curing machine is high-temperature. Low-intensity UV lamp, the curing temperature of printed matter reaches 70°C to 90°C, and the UV curing speed is 4000-5000 sheets/hour. If the power of the UV lamp is increased to achieve the curing speed, the UV curing temperature will be Increased exponentially, unable to meet the strict process requirements of offset printing,

Professional offset printing low-temperature high-speed UV curing machine, using imported low-temperature high-intensity UV lamp, low-temperature high-intensity UV lamp is a high-pressure mercury lamp produced by high-end technology that uses high-purity luminous electrodes and is filled with high-purity luminous gas in an accurate proportion. The working current is small, the temperature is low, and the intensity is high. The luminous temperature is more than 40% lower than that of conventional UV lamps of the same specification, and the luminous intensity is more than 100% higher. The temperature is controlled at 45°C, and the UV curing speed can reach more than 9000 sheets/hour, which meets the low-temperature and high-speed process conditions of offset printing. It is widely used in large-scale printing industries such as cigarette label packaging printing and color printing packaging printing. - Special printing:

Widely used in screen printing ink uv curing, offset printing, letterpress printing, self-adhesive trademarks, metal nameplates, KT boards, glass, ceramics, electronic parts, single-sided circuit boards and other substrates to print crystal ice, frosted, crystal gems, colorful embossing Special effects such as oil. - In terms of painting:

Bright coating on wood surface, gloss on paper, surface coating on plastic floor, fiber optic cable. Instant drying, saving time and high production efficiency. It can make the surface of printed parts achieve high gloss, abrasion resistance and solvent resistance. The conveyor belt has stepless speed regulation and is equipped with an anti-offset device to ensure smooth conveying. Imported Teflon mesh belt, the conveying speed is stable and adjustable, and it can be easily connected with the production line and other equipment. Each set of UV system is independently controlled, and the number of lamps is turned on according to the production. Using special magnesium-aluminum alloy lampshade, concentrating design, high production efficiency. - Electroacoustic industry:

Suitable for glue curing of micro speakers, speaker speakers, receivers, earphones, earplugs, etc.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat