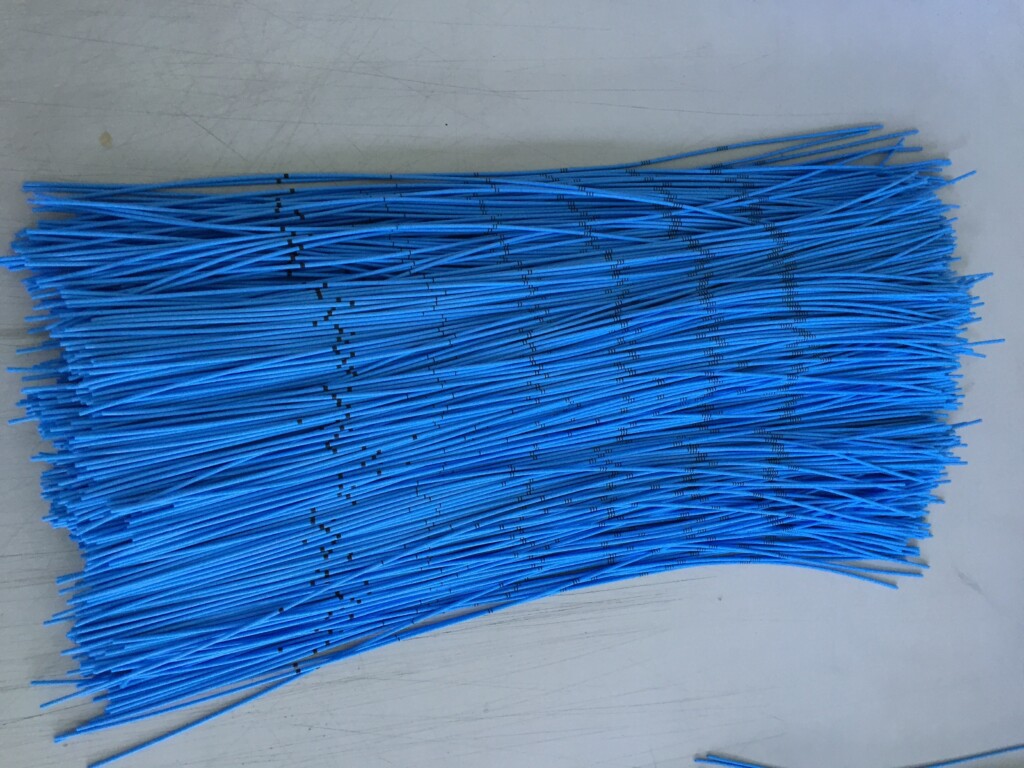

catheter pad printing machine with competitive price

When it comes to printing on catheter tubes, pad printing machines are commonly used due to their versatility and ability to handle small and curved surfaces. These machines are specifically designed to print on cylindrical objects like catheter tubes. Here are some key considerations for a catheter printing machine from DSTAR Machine:

- Adjustable Pad: Look for a pad printing machine that offers adjustable pad height and angle. This allows the printer to accommodate various sizes and shapes of catheter tubes, ensuring proper ink transfer onto the curved surface.

- Tube Holding Mechanism: The machine should have a secure and adjustable tube holding mechanism to keep the catheter tube in place during printing. This ensures accurate alignment and prevents movement or slippage during the printing process.

- Ink System: Check if the machine has an efficient ink system that allows for precise ink transfer onto the catheter tube. The ink system should provide consistent and controlled ink flow to achieve clear and durable markings.

- Speed and Production Volume: Consider the catheter printing speed and production capacity of the machine. Depending on your production requirements, choose a machine that can meet the desired volume while maintaining printing quality and accuracy.

- Size and Format Flexibility: Ensure that the pad printing machine can accommodate a range of catheter tube sizes and formats. It should have adjustable fixtures or tooling to handle various diameters and lengths of tubes commonly used in medical applications.

- Control and Automation: Look for a machine with user-friendly controls and automation features. This can include programmable settings for ink deposition, pad movement, and drying processes. Automation can enhance efficiency and consistency in the printing process.

- Quality and Durability: Consider the build quality and durability of the machine. Look for a reliable manufacturer that produces robust and long-lasting equipment, as catheter tube pad printing requires consistent performance over an extended period.

- Compliance and Regulations: Ensure that the machine and its components meet relevant industry standards and regulations for medical device manufacturing. Compliance with regulations such as ISO 13485 and FDA requirements is crucial for maintaining quality and safety standards.

When considering a catheter pad printing machine, it’s recommended to consult with Shenzhen DSTAR Machine Co.,ltd. We can provide specific recommendations based on your requirements, offer demonstrations, and assist with technical support and training.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat