About the comparison of digital UV printing machine and pad printing machine

As we all know, pad printing is a printing technology with many years of application and development history. UV digital printing is an emerging printing technology. So, how to choose between the two, and what are the advantages and disadvantages of the two?

Advantages of pad printing:

- The cost of ink is much cheaper than that of UV printing. The printing area of the same size, the ink consumed by pad printing is also very small. The cost of a single printing is very cheap

- The production capacity of pad printing is relatively higher. For example, printing 6-color LEGO toys. Pad printing can reach 600 pieces per hour, or even more. UV digital printing cannot achieve this production capacity. In time, UV digital printing can achieve this production capacity, which requires very large workbenches and large-scale printing equipment.

- Compared with UV printing ink, pad printing ink is more environmentally friendly.

- Machine cost: The price of pad printing machine is more affordable than UV digital printing machine

- Pad printing can be used to print concave,convex,flat and some other special shape product.such as Sphere shape

Pad printing for toys

LEGO toys pad printing

PVC ball pad printing

Disadvantages of pad printing:

- The pad printing machine requires a certain operating experience, especially the product printing and register pattern printing that require high precision.

- The pad printing machine needs to make different printing templates according to different product patterns.

- Pad printing is not suitable for small batch orders, because printing plates, fixtures, etc. will increase the cost of a single printing.

- Pad printing requires a variety of printing consumables, such as pad printing ink, ink thinner, ink blade, pad printing plate, silicone pad, fixture, etc.

Advantages of UV printing:

- No need to make a printing plate, it can be printed directly by connecting to the computer.

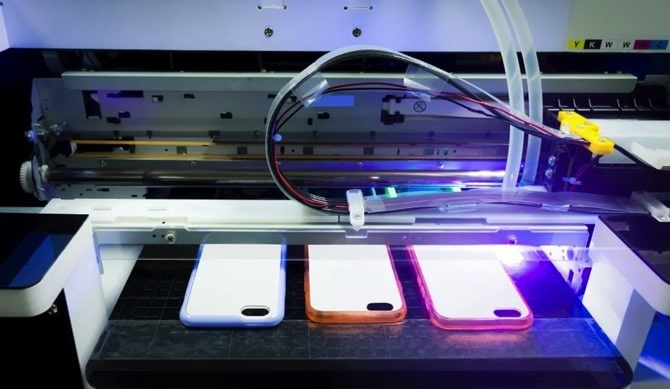

- Flexible application to printing of different patterns and different products.Such as phone cover multi color printing.

- There is no limit to the order quantity of printed products

4.CMYK color printing - After printing, the ink will be cured immediately

Phone cover UV printing

UV digital printing

Disadvantages of UV printing:

- The cost of consumables is high, and the single cost of product printing is higher than that of pad printing.

- The nozzles of UV printing are less selective, and the maintenance and replacement costs are high.

- UV printing is not suitable for the production of large-scale orders, because of technical and machine design factors, the production efficiency of UV printing is not as good as pad printing.

To sum up, pad printing and UV printing have their own advantages and disadvantages. These two printing technologies can complement each other, but cannot replace each other.

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat