high speed drinking cup printing machine with 6 color

Model:DX-JY6

Printing color:6 color

Speed:300 pcs/Min

PET cup height:30-180mm

cup body taper:5-15°

Rim of a cup:¢50-180mm

Maximum printing height:160mm

Main motor power:8KW/AC380V

Total power:about 20KW

Voltage:AC380V/3 Phase

Dimension:L620*W250*H266cm

Packing size:1X20GP (full container)

In the fast-paced world of beverage packaging, efficiency, quality, and speed are paramount. Meet the Automatic High-Speed Disposable Drinking Cup Printing Machine, a cutting-edge solution that revolutionizes the production of disposable drinking cups.

Efficiency at Its Best

Our machine is designed to streamline the printing process, ensuring every cup is flawlessly printed with vibrant, eye-catching designs. With a focus on efficiency, it can handle large volumes of cups with ease, making it the ideal choice for manufacturers looking to meet high demand.

High-Speed Performance

One of the standout features of our machine is its exceptional speed. Thanks to advanced automation and precision engineering, it can print hundreds of cups per minute without compromising on print quality. This high-speed capability significantly increases production output while maintaining consistently excellent results.

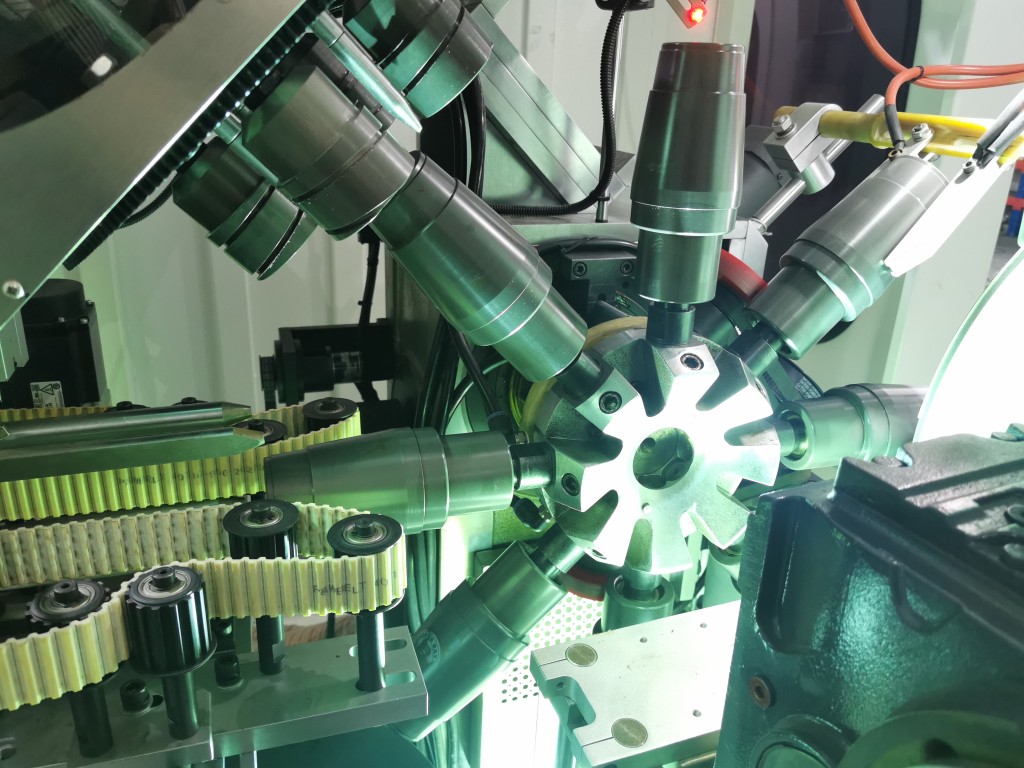

Precision Offset Printing

Offset printing is renowned for its ability to deliver sharp, consistent, and high-quality prints. Our machine employs this technique to ensure your drinking cups showcase intricate designs and vibrant colors. The result is a superior product that stands out on the shelves.

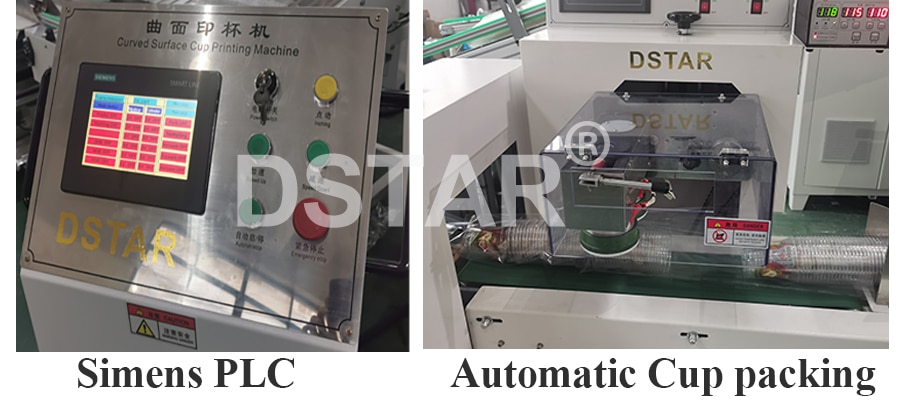

User-Friendly Interface

Operate the machine with ease thanks to its intuitive user interface. Our design prioritizes user-friendliness, allowing your operators to control and monitor the printing process efficiently. Training new personnel is a breeze, reducing downtime and increasing productivity.

Versatile Printing Options

The Automatic High-Speed Disposable Drinking Cup Offset Printing Machine offers versatility in printing options. Whether you require single-color or multi-color printing, it adapts seamlessly to your needs. Customization is also a breeze, ensuring your cups align with your brand’s unique identity.

Low Maintenance, High Reliability

Designed for durability and longevity, our machine requires minimal maintenance, minimizing production interruptions. Its robust construction and quality components ensure a reliable performance that your business can depend on.

Environmental Considerations

We are committed to sustainability. Our machine is designed with eco-friendly practices in mind. It minimizes waste and uses environmentally friendly inks, making it a responsible choice for businesses looking to reduce their carbon footprint.

The Future of Cup Printing

The Automatic High-Speed Disposable Drinking Cup Offset Printing Machine is not just a piece of equipment; it’s a gateway to the future of beverage packaging. With its speed, precision, and versatility, it’s a game-changer for manufacturers seeking to excel in a competitive market.

In conclusion, the Automatic High-Speed Disposable Drinking Cup Offset Printing Machine is the epitome of innovation in the printing industry. It combines efficiency, speed, and quality to meet the demands of modern beverage packaging. Invest in this state-of-the-art machine, and elevate your cup printing capabilities to new heights. Welcome to the future of printing – welcome to success.

- Automatically convey cups, easy to operate, safe and hygienic, and reduce labor

- The cup divider can be customized and adjusted according to the packaged quantity, and the cups are divided smoothly.

- When there is no cup on the cup mold, the printing roller will separate automatically and will not print on the cup mold

- The plate roller gear automatically adjusts the gap, and the printing cup has no shadow.

- There is a special punching machine on the printing plate, which is accurate, fast and easy to operate.

- It is convenient and fast to replace the mold core and cup mold.

- Corona check broken cup function.

- Sampling inspection function of printed cups during work

- The automatic counting is accurate, and the operation of collecting cups is convenient

- Can be packed automatically

- Automatically drive transfer rubber mode

Plastic Cup Offset Printing Machine vs. Screen Printing Machine: Advantages and Disadvantages

Plastic Cup Offset Printing Machine:

Advantages:

- High-Quality Prints: Offset printing provides exceptional print quality with sharp details, vibrant colors, and consistent results. It’s ideal for intricate designs and images.

- High Speed: Plastic cup offset printing machines are known for their high-speed capabilities, allowing for rapid production, making them suitable for large-volume printing.

- Cost-Effective for Large Runs: As the volume of cups increases, the per-unit cost decreases, making it a cost-effective choice for large production runs.

- Versatility: Offset printers can handle various cup sizes and shapes, making them versatile for different cup types and designs.

- Minimal Set-Up Time: Once the machine is calibrated, it can print continuously with minimal downtime, making it efficient for long production runs.

Disadvantages:

- Initial Investment: Plastic cup offset printing machines can be expensive to purchase and set up, which might not be feasible for small-scale operations.

- Not Suitable for Short Runs: Due to the setup time and cost, offset printing is less cost-effective for small quantities, making it less attractive for businesses with varied cup printing needs.

- Ink and Plate Changes: Changing inks and plates for different designs can be time-consuming and may result in some material waste.

Advantages:

- Cost-Effective for Short Runs: Screen printing is cost-effective for small to medium-sized runs, making it suitable for businesses with varied printing needs.

- Customization: Screen printing allows for easy customization, making it a preferred choice for businesses that frequently change cup designs or offer personalized products.

- Durability: Screen prints can be highly durable, especially when specialty inks are used, making them suitable for items like reusable plastic cups.

- Opaque Inks: Screen printing can apply opaque inks, making it suitable for printing on colored or dark cups.

- Simple Set-Up: Screen printing machines have relatively simple setups, making them accessible to businesses with limited resources.

Disadvantages:

- Print Quality: While screen printing can produce good-quality prints, it may not match the level of detail and consistency achievable with offset printing.

- Slower Speed: Screen printing is generally slower than offset printing, which can limit its suitability for high-volume production.

- Limited Color Options: Achieving a wide range of colors and color gradients can be challenging with screen printing compared to offset printing.

- Waste and Cleanup: Screen printing involves the use of screens and stencils, which can generate waste and require regular cleaning and maintenance.

In summary, the choice between a plastic cup offset printing machine and a screen printing machine depends on your specific business needs. Offset printing excels in high-quality, high-volume production but may require a significant initial investment. Screen printing is more versatile for small to medium runs and customization but may not achieve the same level of detail and consistency as offset printing. Consider your production volume, budget, and desired print quality when making your choice.

- printing plate

- UV ink and ink thinner

- Ink cleaner (industrial alcohol or Thinner)

- Cup fixture(customized according cup mold)

- Rubber sheet and double sides adhesive tape

- UV lamp

- plastic film for Cups packing use

DSTAR machine

DSTAR machine

WeChat

Scan the QR Code with wechat